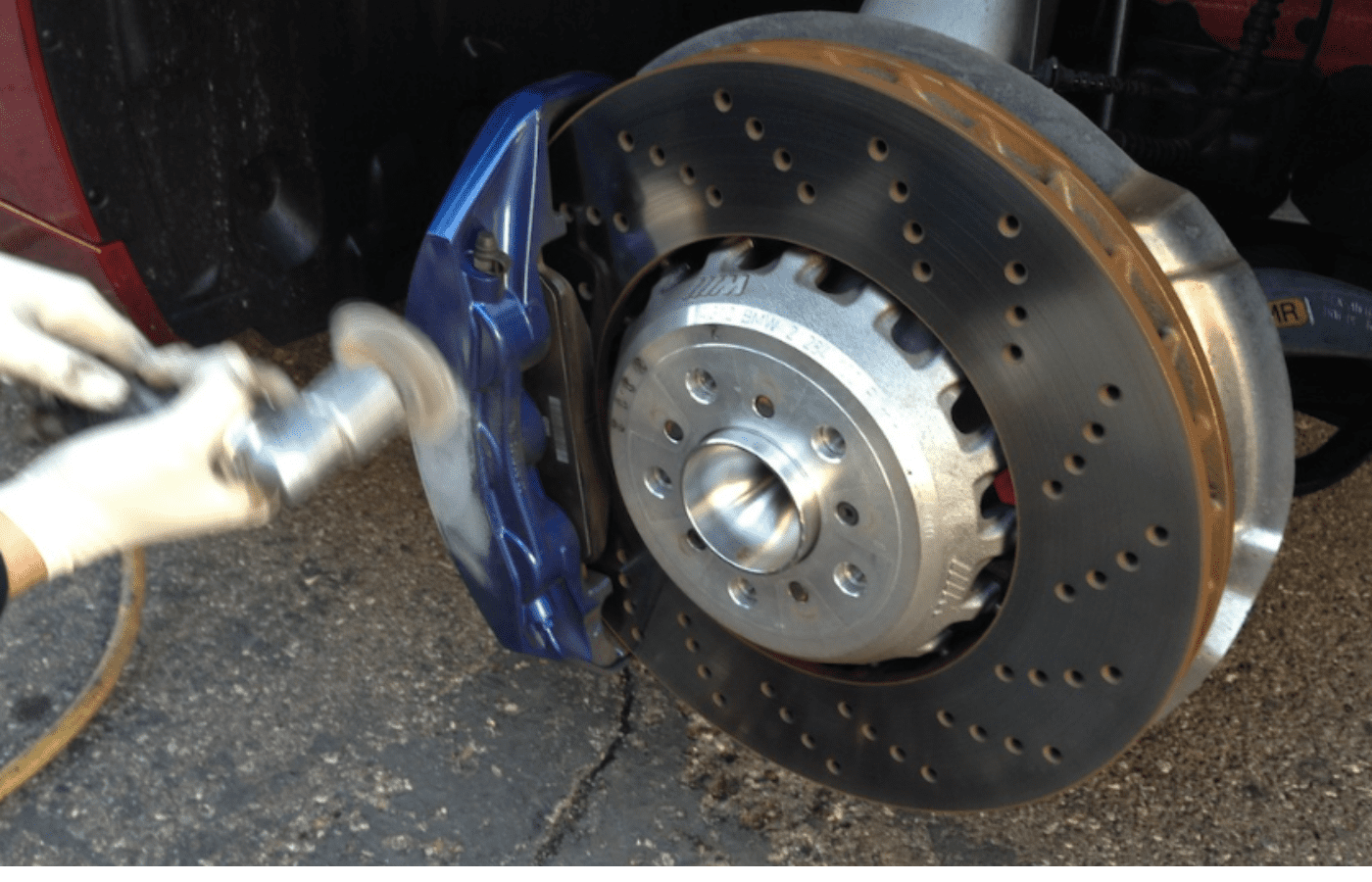

While brake fluid is typically known for its function in cars and is generally left untouched, it can be of great importance when considering powder coating surfaces.

Brake fluid has the potential to cause corrosion on powder-coated items due to its hygroscopic nature, meaning that it can easily absorb moisture from the atmosphere. If not taken into account, the added moisture contained in brake fluid will react with the powder film, resulting in a reduced protection against rust and other potentially corrosive elements.

This can have a detrimental impact on the surface of powder-coated items, most notably causing blistering or cracking. It is therefore crucial that brakes are checked regularly and any excess brake fluid is removed prior to any powder coating processes being carried out.

What Can Damage Powder Coating?

Powder coating is a durable and attractive finish often used on metal products. Despite its strength, several factors can cause it to deteriorate or become damaged.

Heat, ultra-violet light, abrasive cleaning products and weather are all factors that can degrade powder coating. Corrosive chemicals such as acids and alkalis can also harm powder coatings, particularly if these ingredients come in contact with the surface for a prolonged period of time.

Any scratches from sharp objects and physical impacts can weaken the coating, leaving it vulnerable to damage from exposure to other elements.

While powder coating is strong, it should be protected from adverse conditions for maximum performance and life expectancy.

Why Is My Powder Coat Peeling Off?

Powder coating is a popular finishing option due to its durability and smooth finish. However, there are certain factors that can damage or weaken the powder-coated surface.

These include physical abrasion, ultraviolet radiation, extreme temperatures, chemicals and even poor adhesion between the powder-coating paint and substrate.

The slightest bit of force or friction on a powdery finish can cause scratches or chipping while direct exposure to UV radiation over long periods of time can lead to fading or discoloration.

Very high and very low temperatures can also decrease the shelf life of a powder coated item as well as worsen grip strength due to reduced flexibility.

Leftover substances from manufacturing processes can also affect the longevity of a powder coating – for example, residual oils and other materials left behind from a prior process must be removed before application in order for it to stay in good condition for longer.

Adherence between the coating and base structure should also be considered, as uneven coverage will lead to premature deterioration of the finish.

How Long Should Powder Coating Last?

Durability and longevity is an important factor to consider when choosing any industrial or consumer product, and not surprisingly, powder coating is no different.

Powder coating technology utilizes specialized chemicals that are more resistant to wear and tear than conventional paints, offering the potential for a finished product that lasts longer than traditional coatings.

A quality powder coat job should last anywhere from 8-15 years depending on environmental factors such as weather and potential damage caused by impacts or scratches.

Additionally, properties like abrasion resistance can also increase a product’s life expectancy as well as reduce maintenance costs.

It is ultimately critical when assessing how long a powder coated item can be expected to last that all its qualities are taken into consideration.

Can Powder Coating Be Touched Up?

Yes, powder coating can certainly be touched up! In fact, you can easily invest in a touch-up kit and use it as long as the original powder that was used is still available.

A quality touch up job usually requires thorough prep work including heavy sanding, cleaning, and taping off the area to be touched up.

You must then apply a thinner coat of the same powder that was initially used on the item until you achieve the desired thickness.

If the paint has faded over time, or if the job isn’t perfect, then a few additional coats may be necessary for total uniformity.

The key to getting satisfying results with a touch up job is to have patience and pay careful attention to detail throughout every step of the process!

Frequently Asked Questions

Can You Use Brake Cleaner on Powder Coat?

Brake cleaner is a powerful product that is used to break down dirt and grease that has built up in your vehicle’s brakes.

In this case however, it is not recommended for use on powder coat surfaces as the chemicals can strip away the special coating applied to create the desired finish.

Instead, mild detergents with warm water are preferred for cleaning powder coated items, as they will enable you to remove any dirt or other debris without damaging the powder coating.

Additionally, avoiding rough scrubbing and using substances like steel wool on your powder coating job will help safeguard its durability.

Can Isopropyl Alcohol Damage Powder Coating?

Applying heat to powder-coated surfaces can cause the material to melt, peel or discolor over time, which is why it’s important to consider the solvents that might come in contact with your powder-coated surface.

Isopropyl alcohol, with its strong characteristics and wide availability, may be a tempting solvent to use since it is so often used for cleaning and disinfecting surfaces around the home.

However, this solvent should not come in contact with your powder coating as it can degrade its glossy finish – drying out the material and causing damage that can impact how well your coating holds up in the future.

While it’s possible to use certified cleaners specifically designed for treating powder coatings safely, caution should always be taken when handling solvents during projects.

Does WD-40 Damage Powder Coating?

Using WD-40 on powder coated surfaces can be a tricky situation as it is difficult to control the greasy residue that can be left behind.

The lubricant lubricates, cleans and protects but only for a short period of time, which will inevitably lead to a buildup of dirt and grime afterwards.

And if the products aren’t used correctly, it is not unknown for them to start eating away at aging powder coatings. In the wrong hands, product like WD-40 can do more harm than good, so be sure to assess the risks before using it on any powder coated surface.

It may also devalue finishes over time – one of the main causes why people opt for powder coating as it helps protect areas from corrosive elements of weather and environmental factors.

Final Thoughts

Because of its hygroscopic nature, which means that it readily absorbs moisture from the air, brake fluid has the potential to cause corrosion on powder-coated components.

This is the case because of the nature of the powder itself.

In the event that it is not taken into consideration, the added moisture that is contained in brake fluid will react with the powder film, which will result in a decreased protection against rust and other potentially corrosive elements.